Cargo Liners

Revealing the hidden industry

The shipping industry functions largely unnoticed by the public, yet we all depend upon it for our daily goods and services. Except for glimpses of ships passing along the coast or into port we know little of their history or how the seafarers who man the ships live and work on the oceans. We know even less of the commercial nature of the vast industry that underpins shipping or the regulatory authorities that strive to bring order to its operation.

This series of articles “Shipping for dummies” will describe

the different sectors of the industry and follow the historical development of

shipping and its ancillary services.

We start with an examination of the birth of the general

cargo liner and what brought about its demise. Throughout, I will use my

experience in the industry to highlight some of the issues faced by seafarers

in their daily life.

Whisky,

Camels and Tanks

The

general cargo liner

Today,

the general cargo liner is no more but for more than 100 years it was the

primary ship type carrying goods around the world from whisky and camels and

heavy cargo such as tanks and all in the same ship!

She

was owned by Alfred Holt, a pioneer of his time, who, in the start of the

industrial revolution, recognised the value of steam for maritime propulsion.

Experimenting with higher steam pressure than the fledgling steam locomotives

he developed a compound steam engine that not only was compact enough to fit

into a ship but effective in its use of coal.

The

ship was the first in the company that later became the renowned cargo liner

shipping line, Blue Funnel line.

As

a result, S.S. Agamemnon could complete a passage around the Cape of Good Hope

to China in 60 days in comparison to the competing “Tea clippers” under sail

that averaged 123 days! When the Suez Canal opened four years later, in 1869,

so the era of the sailing vessel was finished, and technological development in

ship propulsion created a paradigm shift in the development of maritime

transport that enabled steam ships to dominate international maritime trade.

The

paradox, today, is that general cargo is still carried in ships but most often contained

in containers in ships that are classified as “specialised” container ships

because the unit of carriage is a container. So, what was it that made general

cargo ships special?

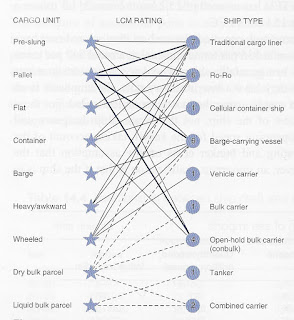

Martin Stopford in his book “Maritime Economics” [2]supplies a further definition for the general cargo ship using a unit of cargo flexibility in the design of the ship.

This “lateral cargo mobility coefficient (LCM) ranks all ships based on their ability to carry different cargo units. Lines linking ship type to cargo unit indicate that the traditional cargo liner ranks highest where more specialised ship types rank lower on the index. Note that he refers to cargo liners not generic cargo ships. Therefore, we need to differentiate between to different types of general cargo ship, the “tramp ship” and the “cargo liner”. The tramp ship had no fixed routes or schedules but took cargo where it could be found and took ballast voyages between ports in the search for cargo. These ships often had a much simpler design structure for the carriage of general cargo.

The

cargo liner was a scheduled service between a fixed range of ports offering the

shipper both a schedule and a fixed cargo rate for his cargo.

We will focus on the cargo liner.

|

|

The classic cargo liner was designed to carry many different types of cargo. With 5 or 6 holds, each sub-divided with tween decks these ships were ideal to store various cargoes.

Hatch

number three and four could have lockers in the tween decks to store and secure

valuable or perishable cargo such as whisky or fruit that needed cooling.

All

hatches had tween decks that could support heavy lift cargo such as locomotives

or wheeled cargo such as cars.

The

lower holds stored everything from steel to bagged cargo to chests of tea, all separated

from each other with dunnage.

Flexibility

came with its challenges.

Stability

calculations were a constant activity to ensure the ship was loaded in a way

that did not undermine the stability of the ship. Also ensuring that the cargo

was protected enough to arrive at its destination in pristine condition was

another challenge.

Whilst

loading crates of bottled whisky in Glasgow it was necessary to have security

personnel in the lockers whilst loading, one from the shore and one from the

ship. Guess who got the job, the most junior apprentice in his smart new

uniform!!

The

first thing the dockers did was to build a wall of crates between their work

area and where we stood. The result was we could not see the crates been loaded

but we could hear breaking glass. Enquiries were responded with a smile. “We

dropped the crate”. I found it good sense not to argue with dockers with their

wicked cargo hooks!

Four

hundred tons of valuable coconut oil loaded in India and destined for the East

coast of the USA arrived as a solid mass because the heating coils failed!!

One

of the tasks of apprentices was to check each hatch after departure from a

discharge port to ensure that all cargo had been unloaded for that port.

Surprise, surprise, I said to the chief officer responsible for load and

discharge of cargo, there is a large steam locomotive marked Calcutta (now

called Kolkata), the port we have just left.! You are joking? No, what do we do

now? It will have to come off at Visakhapatnam, our next port. There will be a

real stink about that.

Flexibility

had another dimension, the ability to load and discharge with ships equipment.

All dry goods whether light or heavy could be handled without shore cranes, a

necessary requirement in many river or surf ports.

Most cargo was handled by two derricks at each hatch configured as a “union purchase”. One derrick was boomed over the hatch and the other positioned over the quay or barge alongside the ship. The lifting wire from each derrick was joined together in a cargo hook. The operation required two winches, one for each derrick lifting wire. By alternatively hauling on one winch and slacking on the other cargo could be transferred from hatch to dockside or barge and vice versa. This was a very easy method to use and flexible enough to handle a variety of cargo units.

The jumbo derrick was

different, being a swinging derrick that was controlled in both lift ,swing and

topping by individual winches. Locomotives, tanks and landing craft were loaded

and discharged in thius way. Note that with only one jumbo derrick, heavy lift

cargo was limited to hatch number 2 or on deck over the hatch. So Centurion

tanks for Jordan were discharged with the jumbo derrick at Aqaba watched over

by no less a person than King Hussein!

Flexibility also

allowed animals to be carrried, mostly on deck, either being lifted singly with

lifting strops or walking on board. A deck load of camels from Port Sudan to Djibouti

was chaotic with local herders shouting, camels braying and a stench that did

not leave the ship until long after we had discharged the camels!

However, flexibility

had a price. Cargo operations were very labour intensive with gangs of dockers

in the hatches and other gangs on the quay or in the barges. It would not be

unusual to have over fifty dockers involved in a load or discharge operation.

In addition, it took days and weeks to load and discharge cargo in a port and

if you add delays due to port congestion it was not unusual for 50% of the

voyage time to be spent in port!

So it is not

surprising that the decline in the general cargo liner was inevitable to be

replaced by the container ship. In 2006 general cargo liners numbered less than

10% of the world fleet with an average age of 29 years![3]

The golden age of

general cargo liners has passed.

.jpg)

Comments

Post a Comment

Lets see what you think!